Latest Version

2.10

January 22, 2025

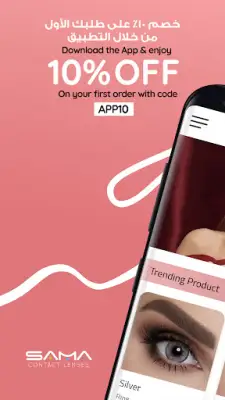

sama contact lenses

Shopping

Android

1

Free

com.sama.samacontactlenses

Report a Problem

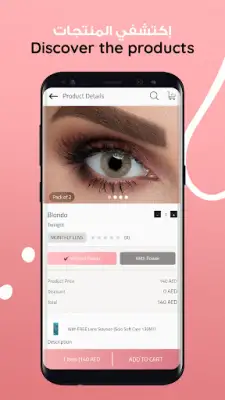

More About SAMA Contact Lenses

The application describes a unique blend of science and creativity that aims to deliver high-quality contact lenses through meticulous design and manufacturing processes. The journey of the SAMA Lenses began in 2012 and reached completion in 2014, after which manufacturing commenced. The emphasis on quality is paramount throughout the entire process, showcasing an unwavering commitment to excellence from inception to delivery.

The manufacturing process of SAMA Lenses starts with the careful selection of materials, followed by an advanced, computerized manufacturing method that ensures high precision. After production, the lenses undergo a rigorous sterilization process, which guarantees that they are completely sterile and safe for use. This attention to detail is key in the contact lens industry, where hygiene and safety are critical for customer satisfaction.

Following sterilization, each lens is subject to a thorough quality control inspection carried out by trained professionals. This human touch in quality assurance allows for a meticulous examination of each product, checking for any impurities and ensuring compliance with international standards. Once the lenses pass this stage, they are packaged and stored under controlled conditions, ready for shipment to customers around the globe.

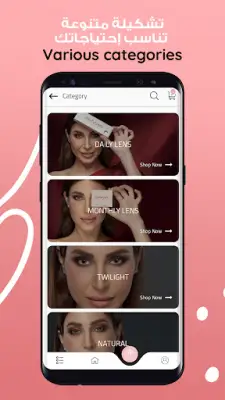

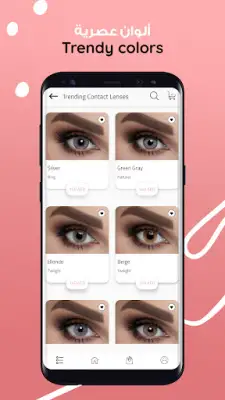

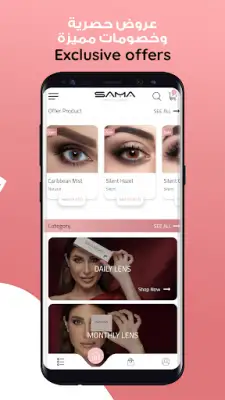

Beyond the initial inspection, SAMA Lenses maintains an additional quality control department that routinely samples finished products. This ongoing evaluation process reinforces the commitment to maintaining high standards and adhering to specifications. Furthermore, customers can conveniently purchase their desired contact lenses through the SAMA contact lenses app, making the entire experience user-friendly and efficient.

Rate the App

User Reviews

Popular Apps